The production of diluted Hypochlorite, from solutions with reduced saltiness or directly from sea water, is a very diffused process, especially in the power stations, in order to eliminate the fouling phenomenon by macro and micro organisms in the cooling pipes which use sea water directly.

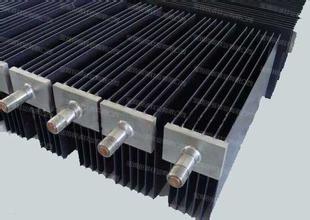

The electrolyser is composed by a cylinder body, usually in plastic, which contains an titanium electrode structure, composed by flat activated Titanium electrodes arranged in series so that the same electrode can work at an extremity of the anode and at the other of the cathode.

The coating is Ruthenium Oxide based plus other Sn, Fe, Ni, Pd additive oxides which make it resistant to the contemporaneous release of both Oxygen and Chlorine and they increase the efficiency towards this.

The electrolyser is sized depending on the potential required in kg/h of Chlorine and the operating pressure and is supplied complete with electrical attachments at the extremities with flanged openings for the entrance and exit of the solution.

Xinxiang Future Hydrochemistry Co., Ltd. supplies both the complete electrolyser and the electrode package in case of replacement of a package at the end of its lifespan. And also the single electrodes in the cases required by the client.

|